Vooner Liquid Ring Conical Port Vacuum Pumps

How “Vaneslip” Affects Liquid Ring Vacuum Pump Performance

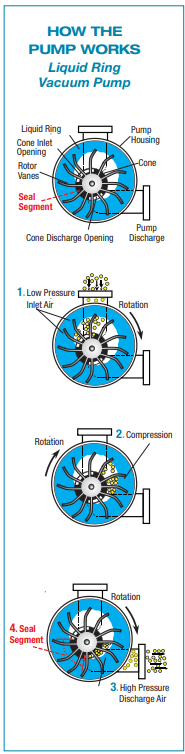

The liquid inside the pump helps to create a seal. The impeller uses centrifugal force to create a ring of liquid around the edges of the offset vanes. This sealant liquid is highly effective but can create some corrosion issues. The most common liquid is water (sometimes called water ring vacuum pumps), but these can be created to work with any liquid type.

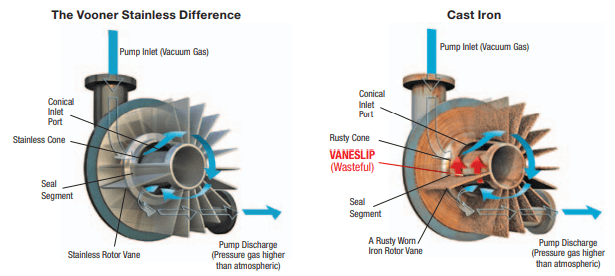

The portion of the discharge gas that is not discharged out of the pump but leaks past the seal clearance between the vane of the rotor and the seal segment of the cone is called “Vaneslip.” Vaneslip allows high-pressure gas to enter the inlet section and, therefore, robs space for new inlet air to enter the pump, thereby reducing the flow of vacuum gas being removed from the process.

With cast iron pumps in operation, the iron oxide (rust) that forms on the rotor and cone surfaces is physically worn away with use, increasing the clearance between the rotary vanes and the seal segment of the cone.

This decreases the seal, which then allows the high-pressure gas of the discharge segment to enter the vacuum inlet section of the pump.

Vooner FloGard stainless pumps have blades that rotate without losing pressure from corrosion, offering greater efficiency.

Click To Download

Vooner FloGard Vacuum Pump Brochure

Manufacturer Testing To HEI Specifications

Performance Standard for Liquid Ring Vacuum Pumps and Compressors – 5th Edition, 2016

The Fifth Edition of the Performance Standard for Liquid Ring Vacuum Pumps and Compressors presents industry standards and factory test methods. Definitions and nomenclature for liquid ring vacuum pumps and compressors are included along with design specifications, operating variables, correction factors, and figures that describe single and/or two-stage flat port plates, conical ports, and test set-ups for vacuum pump performance. Like all HEI standards, there is an appendix for conversion of English to SI units.

Low to High Vacuum (4-26″ HgV; 300-15,000 ACFM); Single Stage Cone Port Vacuum Pumps

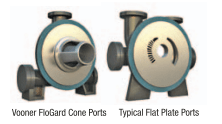

Vooner’s Cone port pumps are the standard of quality in the world market for vacuum solutions involving carry-over of liquids or solids and having the ability to re-establish original clearances and, therefore, recovering performance. Cone port openings are large enough to allow the carryover of process liquids (including condensing spray from the inlet) and erosive solids from the process.

Vooner’s Cone port pumps are the standard of quality in the world market for vacuum solutions involving carry-over of liquids or solids and having the ability to re-establish original clearances and, therefore, recovering performance. Cone port openings are large enough to allow the carryover of process liquids (including condensing spray from the inlet) and erosive solids from the process.

Our liquid ring pumps can handle liquids and solids.

Our two-stage pumps are a better vacuum system if you need higher vacuum levels (above 23″ HgV). By dividing the process, it shares the temperature rise, creating a better seal from the solvent and allows for the greater vacuum pressure.

Cone Port Design Offers Several Advantages For Vacuum Pumps Over Flat Plate Designs:

- Passes slugs of process water and entrained solids easily through Vooner’s

large cone ports - Can re-establish the clearances to regain original performance

- Allows spray condensing in the inlet pipe to pass condensate

through the pump

Vooner Flogard is one of the top suppliers of industrial pumps.

Vooner Flogard is one of the top suppliers of industrial pumps.

We create manufacturing equipment for a wide range of industries, including

- Pulp and Paper

- Power Generation Plants

- Food and Beverage Processing

- Mining

- Chemical

Our experience across multiple industries helps us develop versatile and resilient products across a wide array of applications and harsh manufacturing environments. Have a unique case? Contact our engineers to get started on a plan that works for you. We work with both system upgrades and new pump systems.

The Vooner Liquid Ring Vacuum Pump Competitive Edge

In the manufacturing industry, margins keep getting thinner. You need equipment that is efficient, affordable, and durable. Our pump systems are designed to help you meet production efficiency targets while reducing costs.

The Vooner VaneGard pumps bring a cone port innovative vacuum technology to the market. It is engineered to deliver displacement pumps with peak efficiency and lower initial costs while still being designed for added pump life and reduced repairs. Center to our pumps’ advantages is its patented dual water supply system. This reduces the amount of fresh water your operations require and lowers utility costs.

The VaneGard uses a self-aligning, removable bearing carrier. This innovative design speeds up maintenance and reduces downtime.

Always engineered with an eye on longevity and long-term operating costs, we use stainless steel components designed to extend the pump’s lifespan and minimize life-cycle costs.

- 175 – 10,600 ACFM

- 4 – 26″ HG Vacuum

- Quick delivery

- 3-year warranty

We use a bolt-in design that reduces shipping costs and helps this system bolt directly into your existing system. Our replacement liquid ring vacuum pump systems get you back into production more rapidly. We follow up with extensive technical support and analysis team to help your maintenance team get set up with the least amount of hassle, frustration, and delays. Our team will help you with pump selection to get the correct option for your plant.

On-Site Vacuum Pump Testing

Vooner will bring our test equipment (orifice plates or test manifold) to your plant and perform an orifice test on each liquid ring vacuum pump (Vooner, Gardner Denver…etc.). The data collected is utilized to compare the current dry air performance of your existing pumps to the original manufacturer’s marketing performance curve.

A written survey report will be provided.